Leo Filter Press Stainless Steel Plate andFrame Filter Press Construction and Operation Instructions

The Plate and Frame Filter Press Theory forWorking and Operation from Leo Filter Press,the Filter Press Manufacturer fromChina

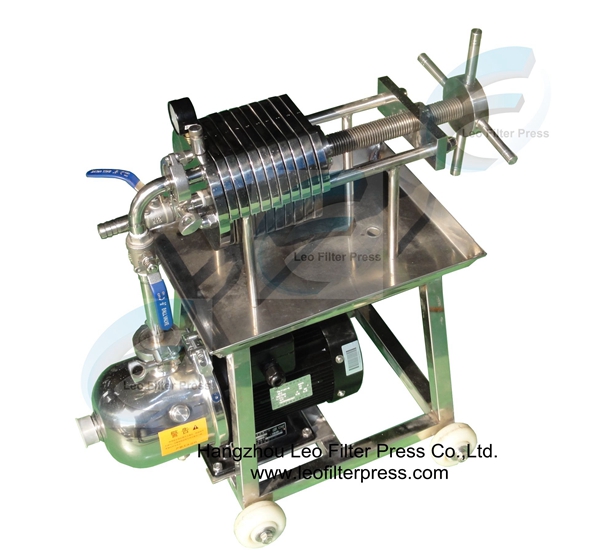

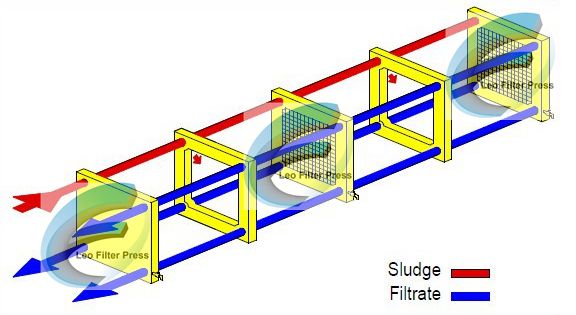

The square plate and frame filter press designed to be multiple layers design, can be used for lower than 50% viscosity solution filtration with a few solid content to clarify,purify etc.The filter press always used for filter out activated carbon,small solid paticles etc.The micro membrane is the primary choice to be the filtering area,no need to filtered by micro filter to get an aseptic filtering condition. To choose square filter plate/frame,then filter press users can get bigger filtering area,big flow rate,wider application for various industries, especially for medicine, chemical and food industries.

Leo Filter Press Stainless Steel Plate and Frame filter press design characteristics:

1. Except the electrical motor,the filter press material adopts SS304 or 316L,can be used for various kinds of solution filtration with different Ph value.

2. The whole filter press system designed to be perfect sealing filtration,less filtrate leakage, better filtering result and higher filtering efficiency.

3. Shift filter press capacity by adding or moving away filter plate/frame,according to different filtering tasks,various filtering media can be chosen.

4. Special designed filter plate surface,advanced structure design, not easy to be distorted and easy to be cleaned,longer filter membrane lifetime,less maintenance and operation cost

5. Stainless steel feeding pump, less electrical power consumption

6. Rubber wheels under the filter press frame,easy to move the filter press ,working spot can be shifted according to requirements

Stainless Steel Square Plate and Frame Filter Press Specifications

Model | Plate | Filtering Area(m2) | Plate Size(mm) | mesh(um) | pressure(Mpa) | Flow rate(T/h) | Power(Kw) | External Size(mm) |

ND-200 | 10 | 0.400 | 200×200 | 0.8 | 0.15 | 3.0 | 1.1 | 650×380×650 |

ND-300 | 10 | 0.900 | 300×300 | 0.8 | 0.15 | 6.0 | 1.1 | 700×500×800 |

ND-400 | 10 | 2.000 | 400×400 | 0.8 | 0.15 | 8.0 | 1.5 | 900×600×1000 |

ND-400 | 20 | 3.000 | 400×400 | 0.8 | 0.15 | 12.0 | 1.2 | 1100×600×1000 |

ND-400 | 26 | 4.000 | 400×400 | 0.8 | 0.2 | 15.0 | 2.2 | 1150×600×1000 |

ND-400 | 32 | 5.000 | 400×400 | 0.8 | 0.2 | 18.0 | 2.2 | 1200×600×1000 |

ND-400 | 38 | 6.000 | 400×400 | 0.8 | 0.3 | 21.0 | 2.2 | 1300×600×1000 |

ND-400 | 44 | 7.000 | 400×400 | 0.8 | 0.3 | 23.0 | 3.0 | 1350×600×1000 |

Note:if need bigger flow rate,please show us your requirements.If there is any explosion-proof requirements,mark it in your requirements | ||||||||