Plate and Frame Filter Pressfrom Leo Filter Press, the Plate and Frame Filter Press Manufacturer from China

Plate and Frame Filter PressWorking Principal and Operation Instructions from Leo Filter Press

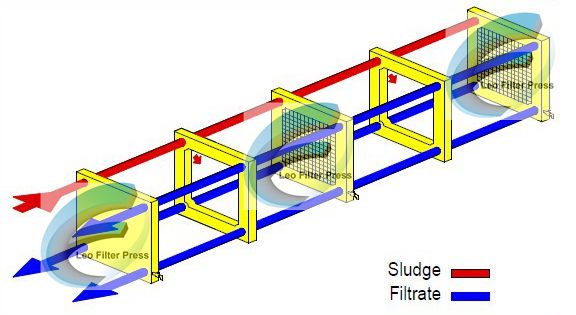

Plate and frame filter press is a traditional oldstyle filter press model,the filter press filtering part style is made from onefilter plate one filter frame then another one filter plate and another filterframe,the filter press cloths will cover on the filter press filter frame towork,now fewer and fewer plate and frame users after chamber filter press wasinvented to use.As the recessed chamber filter plate can endure higherfiltering pressure and filtering temperature.But some industries still useplate and frame filter press to do important product filtration. Though olddesign, filtering units divided into filter plate and filter frame will havegreat advantage when do some special material filtration.When need to shiftfilter cloth/filter plate ,this design will be perfect.

Leo Filter Press B900 Plateand Frame series Filter Press Working Principle and Operation Instructions

The Plate and Frame FilterPress Working Principle:

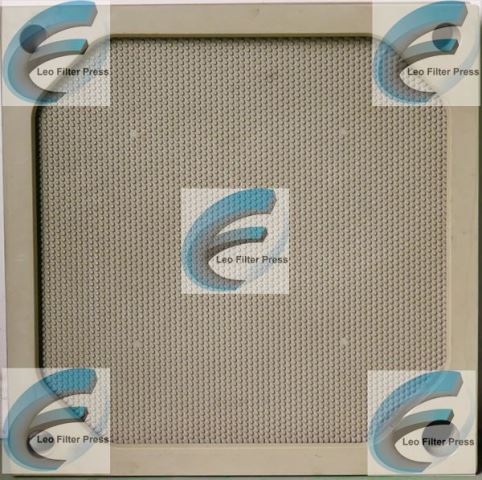

1. All the filter press frame and filter press plates are adopted patent filterplate and frame producing technology, high intensity, low weight, for higherfiltering temperature and pressure filtering operation.

2. Automatically hydraulic closing system, automatichydraulic closing special designed overload protection alarm, reliable operationfor filter press operators

3. Adopted high intensity welding components for whole filter press frame,reasonable overall stress, dependable working performance

4. Easy operation, convenient maintenance during operation,less cost for maintenancein the future.

5. The whole filter press system are designed and manufactured for easy filterplate/filter frame/filter cloth disassemble and replace filter cloth forcleaning, suitable for some special requirement industries such as foodindustry, beverage industry, oil industry etc.

Leo Filter Press B900 Plateand Frame Filter Press Design and Sizing Specification Data

| Filter Press Model | Filtering Area (m2) | Chamber Quantity (pcs) | Chamber Volume (L) | External Size | Weight (kg) | |||

| B | A M | 10/900-U | K B | 10 | 9 | 150 | 2972×1366×1380 | 2360 |

| B | A M | 15/900U | K B | 15 | 13 | 220 | 3216×1366×1380 | 2510 |

| B | A M | 20/900-U | K B | 20 | 18 | 297 | 3521×1366×1380 | 2610 |

| B | A M | 25/900U | K B | 25 | 22 | 363 | 3765×1366×1380 | 2800 |

| B | A M | 30/900U | K B | 30 | 27 | 462 | 4070×1366x1380 | 2950 |

| B | A M | 40/900-U | K B | 40 | 36 | 594 | 4619×1366×1380 | 3230 |

| B | A M | 50/900U | K B | 50 | 45 | 759 | 5168×1366×1380 | 3510 |

| B | A M | 60/900-U | K B | 60 | 53 | 891 | 5656×1366×1380 | 3760 |

| B | A M | 70/900-U | K -B | 70 | 62 | 1056 | 6205×1366×1380 | 4040 |

| B | A M | 80/900-U | K B | 80 | 71 | 1188 | 6754×1366×1380 | 4330 |

Thespecification only for reference during your filter press model sizing.

LeoFilter Press users please check your “Leo Filter Press B900 Plate and FrameFilter Press Operation and maintenance Manual’’ for detailed installation, working,operation and maintenance information.