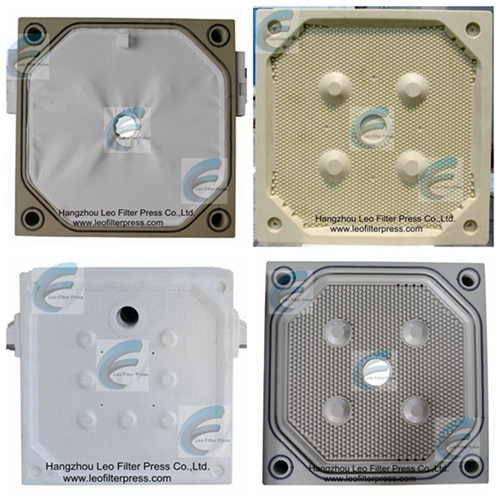

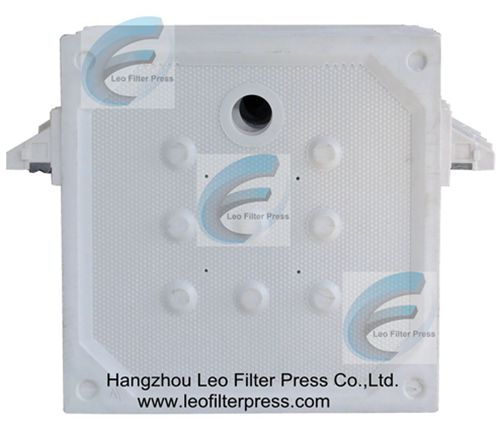

Leo Filter Press X800 Chamber Filter Press Operation and Design Instructions Operation and Working Principle of the Plate and Frame Filter Press from Leo Filter Press Leo filter press offer chamber filter press with a wide range of chamber volume.The chamber filter press has only one kind of filter press plate: chamber recessed filter plate(also chamber filter plate)the filter press can operate in full automatic,semi automatic or manual operation. Leo Filter Press Chamber Filter Press (Recessed Plate Filter Press) Special Design and Operation Instruction: Chamber filter plate structure characteristics 1. the sealing surface will be bigger than filtering surface for half thickness of filter cakes, when to chamber filter plate closed together then there is a filtering chamber. 2.feeding port locates in the center of filter plate or other special required position on the plate,when install filter cloth,the operation will be more complicated than the plate and frame filter presses,we need to roll one side of the filter cloth to a cylinder and push it through the center hole and then re-roll it at the oppsite side and hang it over the filter plate by filter cloth pins on the filter plate top and filter cloth fastening slopes on the right and left side Chamber filter plate styles if according to filtrate discharging way,there are open discharging chamber filter plate and closed discharging chamber filter plate if according to cake washing,there are cake washable chamber filter plate and un-washable one,this can be figure out directly from the port opening on the chamber filter plate.Filter cake washing is a method for solution replacement,during filter cakes' washing,there are many unbalanced parts for washing,but this we can innovate by improve filter press structure design and operating method to reach the best washing result with least washing water consumption. Chamber filter plate dewatering filter cake dewatering can be fulfiled by two method: liquid pushing and membrane suqeezing the normal way for filter cake dewatering is liquid pushing,which carries out at the end of filtration by continously suspension feeding,to feed suspension into the filter cake-fulled chambers to have less and less solids rooms to have solid filter cakes by continuous filtrate discharging,then to have less moisture content filter cakes,but by this way will consumpt lots of time,energy,less working efficiency Membrane squeezing is the more advanced and quicker way for cake squeezing for dewatering,membrane always make from good elasic rubber material or PP material,at the end of filtration,filtrate will be discharged slowly by liquid pushing,then we stop feeding and start membtrane squeezing directly by feed squeezing water or air to the room between membrane and body supporting plate to inflate membranes to squeeze,about squeezing for 10-20 minutes the squeezing preriod will be ended Membrane installation method now have two styles: single size membrane and double size membrane Chamber Filter Plate Material carbon steel,reforced PP and stainless steel for carbon steel material filter plate,it can endure higher distortion force with good elasitc degree,its main advantage is long service time

CollectionWelcome to Hangzhou Leo Filter Press Co.,Ltd.'s website

China.Hangzhou Leo Filter Press Co.,Ltd. |

Home >> filter press machine >> chamber filter press >>

Leo Filter Press X800 Chamber Filter Press Operation and Design Instructions

Edit :Admin View :1446

Content Categories

Product recommendation

Palm Oil Filter Press for Palm Oil Fractionation Project of Oil Refinery Plant Palm Oil Filtering f..

Palm Oil Filter Press for Palm Oil Fractionation Project of Oil Refinery Plant Palm Oil Filtering f.. Filter Press Filter Cloth for Filter Press Operation Replacement,Various Filter Press Cloth Specifi..

Filter Press Filter Cloth for Filter Press Operation Replacement,Various Filter Press Cloth Specifi.. Filter Press Cloth for Mash Filter Press Mash Filter Brewing Filtering Filter Cloth Replacement fro..

Filter Press Cloth for Mash Filter Press Mash Filter Brewing Filtering Filter Cloth Replacement fro.. Mash Filter for Beer Industry Brewery Plant Mash Brewing and Filtering to Replace Lauter Tun..

Mash Filter for Beer Industry Brewery Plant Mash Brewing and Filtering to Replace Lauter Tun.. Small Filter Press in Small Chamber Volume Design Lab Scale Small Size Filter Press..

Small Filter Press in Small Chamber Volume Design Lab Scale Small Size Filter Press.. Filter Press Filter Plate for Plate and Frame Filter Press/Chamber Plate Filter Press/Membrane Plat..

Filter Press Filter Plate for Plate and Frame Filter Press/Chamber Plate Filter Press/Membrane Plat.. Membrane Plate Filter Press,Membrane Squeezing Working Principle Filter Press from Leo Filter Press..

Membrane Plate Filter Press,Membrane Squeezing Working Principle Filter Press from Leo Filter Press.. Various Industrial Filter Press for Industrial Wastewater Dewatering Operation from Leo Filter Pres..

Various Industrial Filter Press for Industrial Wastewater Dewatering Operation from Leo Filter Pres.. Filter Press Working Principle Instructions,to Show How Filter Press Works and What is Filter Press..

Filter Press Working Principle Instructions,to Show How Filter Press Works and What is Filter Press.. Filter Press Parts for Leo Filter Presses Operation Replacement,Various Filter Press Model Filter P..

Filter Press Parts for Leo Filter Presses Operation Replacement,Various Filter Press Model Filter P.. Mining Filter Press,Machine for Mining Slurry Separation from Leo Filter Press,Manufacturer from Ch..

Mining Filter Press,Machine for Mining Slurry Separation from Leo Filter Press,Manufacturer from Ch.. Hydraulic Filter Press Operation,Instruction for Automatic and Manual Hydraulic Filter Press System..

Hydraulic Filter Press Operation,Instruction for Automatic and Manual Hydraulic Filter Press System.. Oil Filter Press,Machine for Oil Filtration after Oil Crusher Operation for Oil Refinery Factory fr..

Oil Filter Press,Machine for Oil Filtration after Oil Crusher Operation for Oil Refinery Factory fr.. Clay Filter Press,Special Designed Filter Press for Clay slurry Filtering from Leo Filter Press,Man..

Clay Filter Press,Special Designed Filter Press for Clay slurry Filtering from Leo Filter Press,Man.. Membrane Filter Press Operation Tip for Leo Membrane Filter Press Users,with Basic Membrane Filter ..

Membrane Filter Press Operation Tip for Leo Membrane Filter Press Users,with Basic Membrane Filter .. Palm Oil Filter Press for Oil Refinery Plant,Oil Filter Press Machine from Leo Filter Press,Manufac..

Palm Oil Filter Press for Oil Refinery Plant,Oil Filter Press Machine from Leo Filter Press,Manufac.. Filter Press Cloth,Replacement Filter Press Cloth in Various Specification and Material for Sludge ..

Filter Press Cloth,Replacement Filter Press Cloth in Various Specification and Material for Sludge .. Manual Hydraulic Filter Press, Plate and Frame Filter Press in Manual Operation by Manual Hydraulic..

Manual Hydraulic Filter Press, Plate and Frame Filter Press in Manual Operation by Manual Hydraulic.. Chamber Filter Plate,Filter Press Plate for Recessed Chamber Filter Press Plate Replacement from Le..

Chamber Filter Plate,Filter Press Plate for Recessed Chamber Filter Press Plate Replacement from Le.. Hydraulic Filter Press,Plates Pressed by Filter Press Hydraulic System,Manual or Automatic Hydrauli..

Hydraulic Filter Press,Plates Pressed by Filter Press Hydraulic System,Manual or Automatic Hydrauli..

Link:

small scale filter press | Automatic Filter Press | Filter Press Cloth | membrane filter plate | Automatic Filter Press | Gasketed Filter Press Plate | Filter Press Filter Cloth | Manual Hydraulic Filter Press | Filter Press Cloth | Mash Filter Press | Mash Filter Plate | Plate and Frame Filter Press Filter Frame | Plate and Frame Filter Press | Oil Filter Press | Chamber Filter Press |

China.Hangzhou Leo Filter Press Co.,Ltd. www.filterpress.tech Copyright © 2010-2029 All Rights Reserved.

Email: yankeeyang@vip.126.com leofilterpress@hotmail.com

Email: yankeeyang@vip.126.com leofilterpress@hotmail.com